Unreliable local suppliers often disrupt production schedules with missed deadlines and poor quality parts. Outsourcing your machine shop work to domestic vendors opens up access to new manufacturing technologies and specialized expertise.

At Ultra Precision, we deliver reliable, high-precision components from our advanced Florida facility. Our investment in automation and decades of experience ensure consistent quality for every project we undertake.

Here are the top 5 states in the U.S. to outsource your machine work:

#1. Florida Machine Shops

Florida’s manufacturing GDP grew 67.8% in recent years, rising to $73 billion in 2022. This growth has ranked Florida eighth in the United States for manufacturing employment. The state is now home to a workforce of over 422,000 individuals in the industrial field. With the number of aerospace and defense companies located along the Space Coast, machine shops in Florida are highly capable of machining exotic alloys like Inconel or machining parts to rigorous specifications.

The state’s pro-business policies and robust workforce create a strong environment for manufacturing operations suited to handle work from other states or countries. Companies looking to outsource their projects to Florida machine shops benefit from a large talent pool and a state government that supports industrial growth. These factors make Florida a reliable choice for outsourcing high-value machine work, especially for projects in the aerospace or defense sectors.

Best Machine Shop for Aerospace Work in Florida

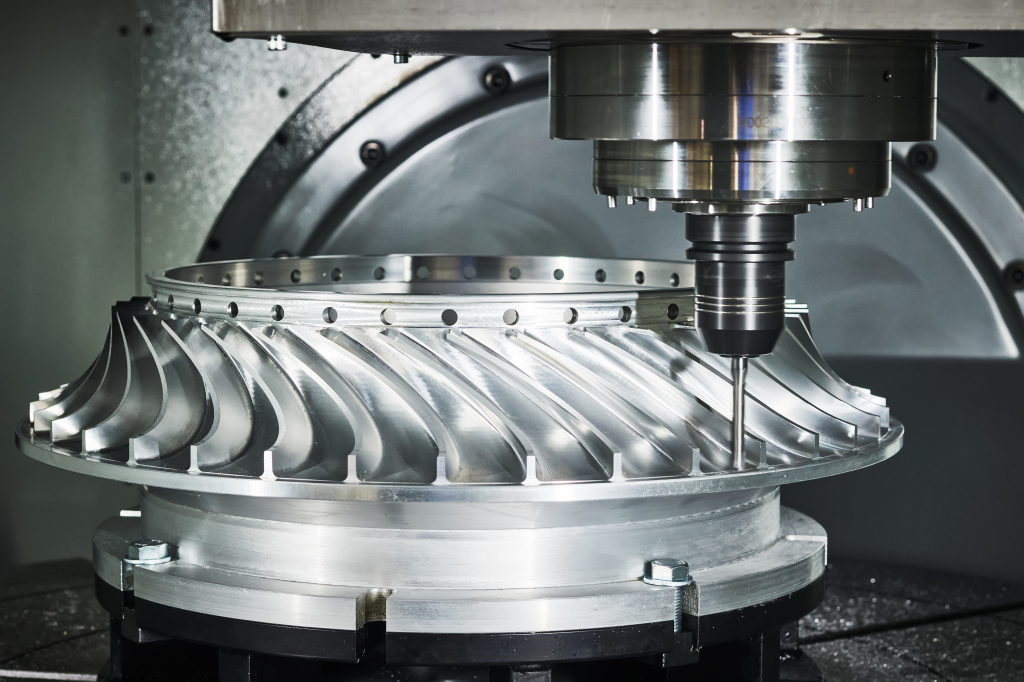

Ultra Precision is an ISO 9001 and AS9100 machine shop in Florida that utilizes 5-axis automation to produce complex parts and employs lights-out machining strategies for continuous, unattended production of high-volume orders. These automated processes increase production capacity and shorten lead times for clients without compromising part quality.

Ultra Precision also has extensive experience serving customers in the demanding aerospace and defense sectors. This background has cultivated a proficiency in machining high-performance materials like Inconel and titanium to increasingly tight tolerances and complex geometries. The technical capabilities of Ultra Precision ensure that all components are manufactured to precise, verifiable client specifications.

Ultra Precision provides several value-added services to support manufacturing needs from start to finish for out-of-state clients:

- Prototyping: They specialize in expedited prototyping and short-run production. Advanced 3D CAD and CAM software helps refine designs and quickly machine parts for functional testing and approval.

- Contract Manufacturing: The shop is equipped for high-volume production to fulfill long-term contracts. Contract manufacturing is ideal for recurring parts that require consistent quality and reliable delivery schedules.

- DFM Services: The team offers Design for Manufacturability (DFM) assistance. They provide guidance on material selection and design modifications to ensure efficient and reliable manufacturing.

- Quality and Inspection: Ultra Precision uses Coordinate Measuring Machines (CMM) to verify that all components meet exact specifications. This process provides detailed inspection reports and ensures dimensional accuracy for every part.

- ITAR Registered: They’re also an ITAR-registered machine shop that’s compliant with all regulations for machining defense-related components and maintaining secure CUI protocols.

#2. Pennsylvania Machine Shops

Pennsylvania has a strong concentration of machine shops specializing in industrial components. As part of the historic “Rust Belt,” Pennsylvania has jump-started its manufacturing economy in recent decades with a steady flow of engineering talent from top state universities into machining companies. Its deep history in the tool and die industry has created a specialized manufacturing ecosystem. The state’s machine shops are highly skilled in creating complex molds, fixtures, and production tooling.

TriState Manufacturers is a manufacturing directory, showcasing manufacturing company listings for a broad range of sectors and industries, and working to collectively improve Pennsylvania’s reputation as a manufacturing haven. The proximity of Pennsylvania companies to major East Coast markets can reduce shipping times and costs for regional distribution. This efficiency is a critical advantage for businesses that rely on just-in-time inventory systems.

#3. Wisconsin Machine Shops

Wisconsin is a major center for industrial, agricultural, and heavy equipment manufacturing. The state’s economy is heavily focused on producing industrial machinery, fabricated metal products, and engines, which are all projects that rely heavily on experienced and knowledgeable machine shops. This concentration of ISO-certified and other qualified machine shops creates a stable and experienced manufacturing environment for businesses to explore outsourcing specific types of machining work.

The state provides a specialized supply chain for heavy industrial projects where manufacturers and OEMs have consistent direct access to foundries, metal fabricators, and suppliers of industrial-grade materials. Companies like Caterpillar, Oshkosh, and John Deere are just a few internationally recognized brands with extensive operations in the state. Wisconsin’s workforce is skilled in producing the large, complex components required by the agriculture, mining, and construction industries, with adherence to tight tolerances even on high-volume production runs.

#4. Texas Machine Shops

Texas’s manufacturing industry continues to expand with the addition of 2,000 new jobs in May 2025. This job creation is part of a consistent upward trend for the state’s industrial sector, including advanced work in machining high-performance parts for the semiconductor industry, which is quickly expanding within the United States. An expanding labor pool increases overall production capacity and ensures a stable environment for outsourcing partnerships.

Aerospace has recently become another critical industry within Texas. SpaceX moved its primary operations there, and this has spurred the growth of a sophisticated local supply chain that keeps efficiency high and costs competitive. Local machine shops in Texas have developed the expertise to produce high-precision components for these demanding projects. With the consistent presence of oil and gas companies in the state, countless new ISO-certified or ITAR-registered machine shops have opened their doors in Texas to help support the exponential growth in the area.

#5. Michigan Machine Shops

Michigan is the historical center of the American automotive industry, but the state economy has grown in recent years to include billions of dollars in the aerospace, defense, and medical device industries. With such a documented history of automotive manufacturing, Michigan machine shops are highly specialized and can support the supply chains for vehicle manufacturing and other demanding sectors. Companies from other states looking to outsource their machine shop gain direct access to a network of suppliers built for high-volume production when finding a service provider in Michigan.

The state’s workforce is deeply familiar with automotive quality systems, amongst other regulatory policies. For example, engineers and machinists understand the rigorous standards required for vehicle components. This knowledge ensures that production meets the specific IATF 16949 requirements common in the industry.

Benefits of Avoiding Overseas Machine Shops

Outsourcing to overseas machine shops introduces significant operational hurdles. These issues can disrupt production schedules and compromise the quality of finished parts. A domestic supplier provides several distinct advantages and avoids these problems:

Stronger Intellectual Property Protection: Domestic machine shops operate under United States intellectual property laws. These laws provide robust protection for proprietary designs and sensitive technical data. This legal

Increased Supply Chain Security: A domestic supply chain is shorter and less complex than an international one. It is not vulnerable to international port closures, geopolitical conflicts, or lengthy customs delays. This stability creates more predictable production schedules and reliable delivery timelines.

Better Communication and Quality Control: Working with a domestic shop eliminates time zone barriers and language difficulties. Direct communication allows for faster problem-solving and clearer design collaboration. On-site visits for quality verification are also simpler and less expensive to conduct.

Reduced Lead Times: Domestic manufacturing removes the need for transoceanic shipping. Finished parts are not subject to unpredictable delays in customs or at sea. This results in significantly faster turnaround times from order placement to final delivery.

Simplified Regulatory Compliance: U.S.-based machine shops are required to follow domestic manufacturing regulations. They have direct experience with standards like ITAR for defense projects and AS9100 for aerospace. This ensures that all parts meet the necessary legal and quality requirements without extra oversight.

AS9100 Certified Machine Shop for Aerospace and Defense Machining

Outsourcing machine work within the United States strengthens supply chain stability and ensures proper quality control. Florida’s skilled workforce and advanced industrial base establish it as a top-tier location for manufacturing.

At Ultra Precision, we combine advanced automation with decades of expertise to deliver high-quality components for critical industries. Our team is ready to meet the demands of your most challenging projects.

Click below for a quote and to learn more about our advanced manufacturing capabilities.