Prototype Parts & Short-Run Production

5-Axis CNC Machining

DFM Services

Contract Manufacturing

Aerospace & Defense Machining Services

Our machine shop provides AS9100-certified aerospace and defense machining services from fast turnaround prototyping to production while holding tight tolerances on complex part designs using specialty metals, alloys, and plastics.

Prototyping & Short-Run Production

Ultra Precision Machining provides prototyping and short-run production services that are custom-tailored to the unique demands, part designs, and materials used by Florida’s aerospace and defense industries. Supported by advanced three-dimensional CAD and CAM modeling software, our knowledgeable team can suggest improving the precision and manufacturability of early prototype designs and producing machined parts for additional testing requirements. Once finalized prototypes are approved, moving to full production is a seamless transition, using our proven processes and modern machining and inspection equipment.

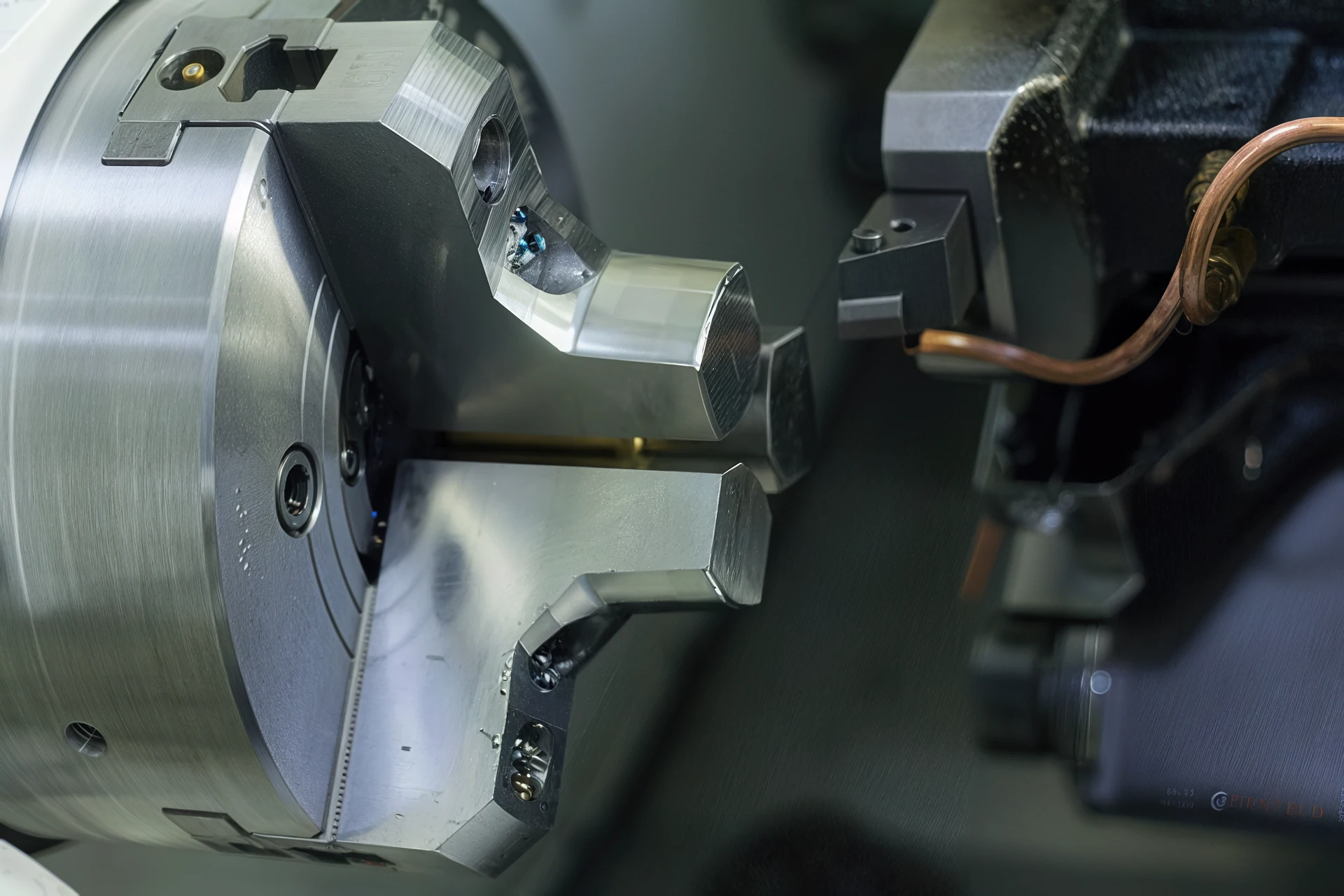

5-Axis CNC Machining

Our ultra-precise 5-axis CNC machining, conducted under strict AS9100 quality standards, delivers exceptional accuracy for high-performance parts made from conventional and specialty materials. With our advanced DMG MORI DMU 50 5-Axis CNC, we efficiently manufacture components with complex features, deep cavities, and tight tolerances that hold up to rigorous post-machining inspections. Backed by extensive industry experience and cutting-edge equipment, Ultra Precision consistently produces precision-engineered parts that align with the stringent demands of our customers in the aerospace, defense, and space industries.

DFM Services

Ultra Precision Machining is dedicated to helping customers from all industries refine their designs to improve manufacturing efficiency and overall production costs and deliver reliable performance in demanding applications. While our AS9100 certification restricts us from providing true design services for aerospace components, we rely on our deep experience from multiple industries to offer design for manufacturability guidance. Whether it’s suggesting alternative materials to improve machinability and performance or assisting customers struggling to secure bids for complex machining projects, we focus on delivering practical solutions that streamline production and address industry challenges.

Contract Manufacturing

As an ISO 9001 and AS9100-certified machine shop in Florida, we specialize in contract manufacturing for customers in the aerospace and defense industries. Our facility and knowledgeable team can efficiently transition prototype projects and supplied part designs into full-scale production for contract manufacturing. Our adaptable machining capabilities allow us to balance production levels that meet tight deadlines, supporting high-volume runs without compromising quality or cost efficiency. Ultra Precision can meet routine monthly, quarterly, and annual high-volume manufacturing demands and also provide supplemental assembly services as needed to streamline production further and reduce overall costs.

Can’t find what you’re looking for?

try searching for a keyword below.

Contact us today for a free estimate.

"*" indicates required fields