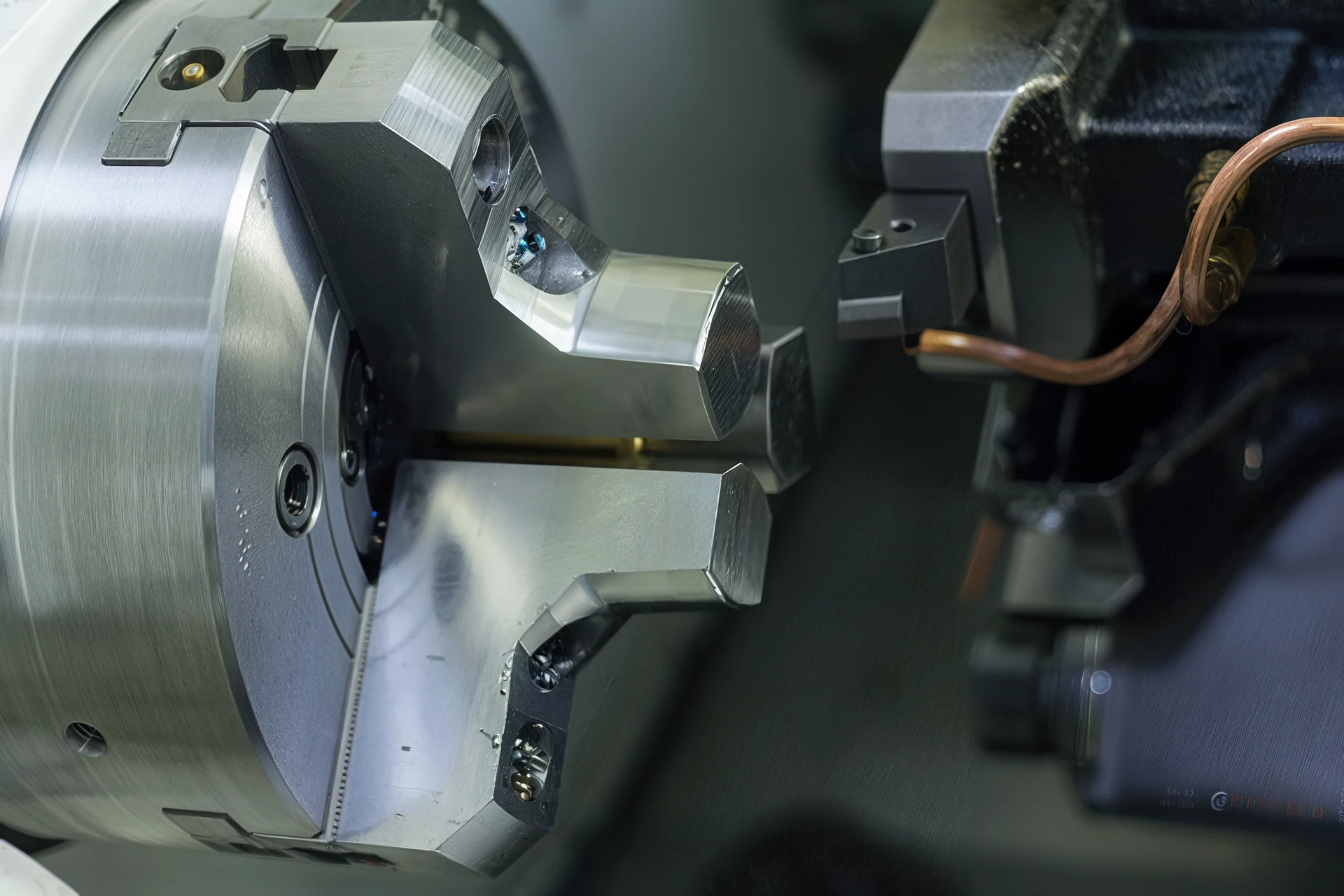

ITAR & AS9100 Registered Machine Shop

As an ITAR and AS9100-registered machining shop, Ultra Precision Machining is uniquely qualified to provide exceptional accuracy and quality results for products used in the aerospace and defense sectors. Our commitment to quality, competitive pricing, and small business flexibility allows us to stand out from other machine shops and offer the precise accuracy that all of our defense and aerospace customers deserve. Our team will work with you to find the best solution for your unique machining needs, prioritizing efficiency, precision, and quality with every job while remaining compliant with all accompanying regulations.

Quality & Precision for ITAR & AS9100-Registered Machining

At Ultra Precision Machining, our mission is to make high-quality, high-precision machine parts for the defense and aerospace sectors. We pride ourselves on the component and part quality rating with our many different customers across several industries, and we strive to meet the expected tolerance limits, complex part geometries, and other specifications that the aerospace and defense industries call for. Our quality department maintains a comprehensive system to ensure the highest level of quality is achieved at all times with every job. Additionally, our AS9100 certification, ITAR registration, CMMC commitment, and SAM registration highlight our commitment to continuous improvement, overall customer satisfaction, and regulatory requirements.

Handling CUI Data

Ultra Precision Machining is an ITAR-registered machining company, which means we are compliant with the legal requirements and regulations regarding products and services in the defense industry. A major aspect of this is keeping data and technology information, or CUI data, properly secured. CUI or Controlled Unclassified Information is the critical data required to manufacture components (3D models, drawings, process data, etc). We are committed to continuous development on how we secure, utilize, and transmit CUI and/or ITAR data in our operations. To maintain this security, we have implemented end-to-end data encryption, data loss prevention, and access control measures for all of our data. Customers from the defense industry experience peace of mind when partnering with us, in addition to receiving precision quality solutions.

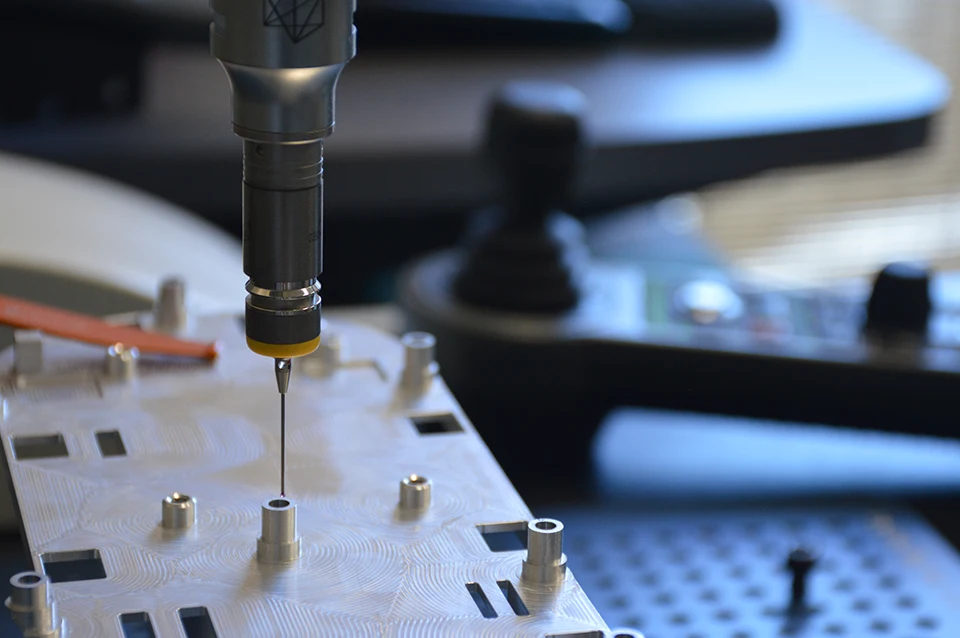

Design for Manufacturability Advice

As an AS9100-certified and ITAR-registered machining company, we can offer valuable manufacturability advice for your parts, all while being compliant with regulations and standards in relevant industries like defense and aerospace. Before we begin the manufacturing process, our team of engineers will work with you to identify the potential for cost savings on your parts as well as the potential for improvement in part efficiency, ease of manufacturing, and dimensional accuracy. The aerospace and defense industries warrant exceptional attention to detail, so Ultra Precision implements solid 3D models to ensure the accuracy each customer desires. Our CAD and CAM services can make models from scratch, and we can also make use of your 3D models for production.

Contact us today for a free estimate.

"*" indicates required fields